Series: PUMA

SHINGLED TECHNOLOGY

Over 555Wp & Over 660Wp

Shingled technology eliminates traditional ribbon connection with shingles connected in series. By removing the soldered ribbons, the active area of the moduleSee photovoltaic (PV) module is improved and thermal stresses are reduced – resulting in exceptional efficiency and reliability over standard interconnections. Puma modules are based on the shingled technology which allow a higher cellsThe smallest semiconductor element within a PV module to perform the immediate… density than standard half-cut modules.

CellsThe smallest semiconductor element within a PV module to perform the immediate… are cut in 5 or 6 pieces, the obtained “shingles” are assembled in strings by connecting front and rear edges of consecutive shingles with an Electrical Conductive Adhesive (ECA).

The ECA replaces the Copper Interconnection Ribbons usually soldered on solar cellsThe smallest semiconductor element within a PV module to perform the immediate…, providing a flexible interconnection and avoiding the thermal/mechanical stresses on the Silicon – Copper interface.

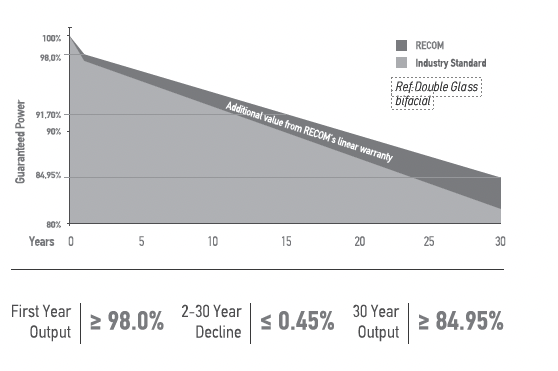

The PUMA moduleSee photovoltaic (PV) module with power class over 555Wp, efficiency up to 21,6% and 25 years product & output warranty is:

- Best “Value for money” choic

- Ideal for rooftop installations (in the

same size of the rooftop,

more power can be installed

compared to standard modules) - Low LCOE

The PUMA module with power class over 670Wp, efficiency up to 21,6% and 25 years product & output warranty.